juxinde@used-equipments.com +86 13992560725

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2023-03-24 Origin: Site

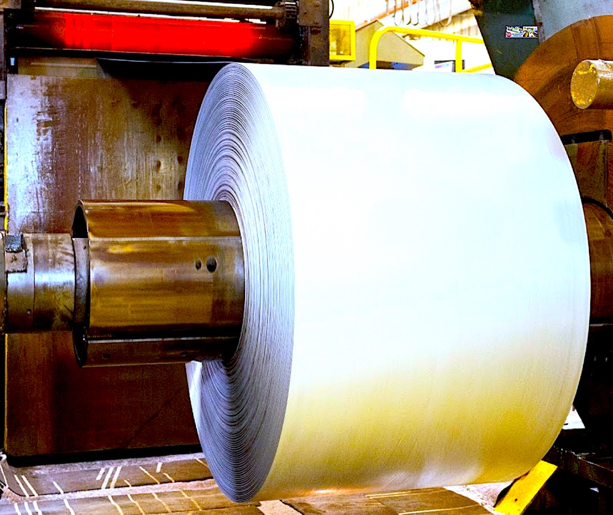

Steel pickling refers to the treatment used to remove impurities, rust and scale on the surface of the material.During thermal processing,a layer of oxide (called "scale" because of its scaly appearance) forms on the surface of the metal.Before most cold rolling processes, previously hot rolled steel goes through a pickling line to remove surface scale and make it easier to work.To restore optimum corrosion resistance, the damaged metal layer must be removed to expose the full alloy stainless steel surface.To remove this oxide layer,the material is dipped in a vat called a "pickling solution."Kimchi wine comes in many forms.Carbon steels with less than 6% alloy content are usually pickled in hydrochloric or sulfuric acid.For steels with a higher carbon content, a two-step pickling process with additional acids (phosphoric,hydrofluoric and nitric) is required.Steel processors that provide hot and cold rolling services typically encounter two different types of scale high temperature scale and low temperature scale.The high temperature grinding process creates three layers of iron oxide that form on the material after temperatures above 1070F.Low temperature scale develops in programs using temperatures below 1070.

Hydrochloric

Advantages:

Reduced heating costs since the pickling solution is used at room temperature

Wider descaling

Reduction of hydrogen permeation through diffusion

Reduces deposition of iron salts on pickling surfaces

shortcoming:

Smokes when heated above ambient

Acid recovery systems are expensive

More corrosive to equipment

Magnesium Disposal costs are higher than sulfuric acid

sulfuric acid

advantage:

Acid can be refreshed more frequently

Increased temperature reduces acid concentration for effective pickling

Easy recovery of ferric sulfate

The pickling rate can be controlled by changing the temperature

shortcoming:

Greater acid attack on base metals.

Hydrogen diffuses more into steel

Pickling residues are more viscous

Acid solutions must be heated

Following the steel pickling process, steel plates typically oxidize after prolonged exposure to high humidity atmospheric conditions. To counteract this, apply an oil film or other waterproof coating to create a moisture barrier in the air.